Since 2001 IODA has a complete Free Form production line, which is updated every year.

In fact, IODA can create special industrial lenses and glass moulds, spheres, aspheres and Free Form surfaces or lenses, whose profile is developped by an algorithm.

IODA has studied methodologies and tools for CAD-CAM analysis, for geometric modelling and CNC manufacturing.

The Free Form production line can be divided into three macro-groups:

- 1 Hardware

- 2 Software and knowledge

- 3 Measuring

1 -Hardware.

IODA Free Form production uses three Optotech industrial machines: ASP100CNC , ASM100CNC and ASP200CNC.

ASM100CNC Grinding and lapping machine.

Flexibility due to 4 CNC axes and an innovative tool concept, which can grant a fine grinding of spheres and aspheres with integrated edging.

Grinding of aspheres with peripheral grinding wheel for highest precision.

Working Range Ø 10 to 120 mm (Spherical); Ø 10 to 240 mm (Asphere Mode) .

The two tools follow a CAD drawing with high precision position.

.

ASP200CNC Pre-polishing machine.

The ASP 200 CNC is a wheel polishing machine for pre-polishing moulds for plastic ophthalmic lenses or industrial lenses.

The unmatched polishing concept with the flexible polishing wheel allows a high precision production of premium glass moulds or special industrial lenses.

The machine works in 4-Axis CNC polishing operations (X, Y, Z, C). This is the State-of-the-art drive and spindle bearing technology: spindles with multiple bearings to guarantee a maximun precision guide.

.

ASP100CNC Polishing machine.

.

Optimal kinematics machine for processing aspheres, progressive and Free Form surface, when highly reproducible results are required, thanks to the vertical tool spindle, using a flexible surface polishing tool or a topographic correction polishing tool.

Using this machine we can realize a high polishing surface quality. We are anyway exploring new boundaries of lens machining, finding undescovered possibilities of usages in the market, because of its characteristic surface roughnesses.

2 -Software and knowledge.

IODA has a technical department, with more than 30 years of experience, who can study the best solution for your needs.

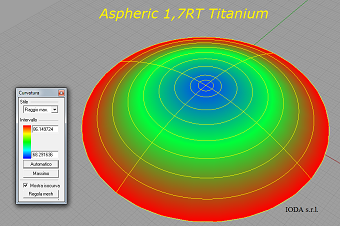

Thanks to the cooperation with the University of Padova, IODA has created a new software called “Ray Tracking” which allows to calculate with great precision the vision ray and therefore calculate the ideal aspheric correction for any application.

We use CAD programs to develop and create a lens virtual profile, and then, create a path for the tool.

3 -Measuring

The high precision surface lens needs a refined control system which can check every point of the surface created to guarantee perfect images without any loss of quality.

The control system developed by IODA can verify the “roughness” of the surface that has been machined, thanks to microscope, special viewers and highly qualified technicians.

The control of the lens geometry is verified with interferometric and surface mapping systems, capable of highlighting differences between the virtual profile and the actual profile of the lens.

We can develop and check individual parameters for our customers’ demands, in order to meet the market needs.

In each lens, you can find all the commitment and knowledge of a company whose main business is the quality of its products.

[maxbutton id=”2″ ]

Italiano

Italiano